Produktkonsultation

Din e-mailadresse vil ikke blive offentliggjort. Påkrævede felter er markeret *

As a high-performance engineering plastic, polybutylene terephthalate (PBT) exhibits excellent processing performance in many fields such as injection molding, extrusion molding, thermoforming and surface treatment. It is widely used in the automotive, electronics and home appliance industries and has become an important material choice in modern manufacturing.

In injection molding, the excellent fluidity of PBT resin enables it to efficiently fill complex molds and form precise geometric shapes. This fluidity not only improves production efficiency, but also significantly reduces the incidence of molding defects, including bubbles, weld lines and poor filling. In addition, the melting temperature of PBT is about 220°C. This moderate temperature enables low-energy and efficient production during the injection molding process, thereby effectively reducing production costs. PBT's excellent performance in maintaining mold details ensures the manufacture of high-precision parts, and has therefore been widely used in the automotive, electronics and home appliance industries.

PBT's ability in extrusion molding is also remarkable. The extrusion molding process heats the plastic material to a molten state and forms various products such as pipes, profiles and films through a mold. Thanks to its good fluidity and stability, PBT can maintain uniform physical properties and dimensional accuracy during the extrusion process. Especially in the production of cable insulation and outer sheath, the uniformity of PBT significantly improves the safety and reliability of the cable. In addition, the extrusion process of PBT can also be co-extruded with other materials, broadening its applicability in different application fields.

In terms of thermoforming, PBT also shows excellent processing performance. The thermoforming process heats the plastic to a softened state and then uses a mold to form it, which is suitable for manufacturing thin-walled parts and products with complex shapes. The thermoforming characteristics of PBT ensure good dimensional stability during the heating process, which is suitable for the production of products such as automotive interiors and home appliance housings. This processing method not only improves production efficiency, but also effectively reduces material waste, which is in line with the concept of sustainable development of modern industry.

The surface treatment ability of PBT is also a highlight of its processing. Its good surface finish enables PBT to be surface treated by various methods such as spraying, printing and film lamination to meet the aesthetic and functional requirements of different products. The excellent adhesion of PBT ensures that the coating and printed patterns can be firmly attached, enhancing the wear resistance and weather resistance of the product during use.

Din e-mailadresse vil ikke blive offentliggjort. Påkrævede felter er markeret *

Karakter: MY08-serien Anvendelse: Elektronik og elektriske apparater Ydeevne: Varmeældningsbestandighed, god steriliseringsevne, god opløsningsmiddelresistens RARU Bemærk: Tilpasning af di...

Se detaljer

Karakter: MY10-serien Anvendelse: Autodele (nye energi- og hybridbiler) Ydeevne: Varmeældningsbestandighed, træthedsbestandighed. lav vandabsorption. Bemærk: Tilpasning af differentierede ...

Se detaljer

Karakter: MY10-serien Anvendelse: Filament spinding, kemisk fiber Ydeevne: Elasticitet, høj farveægthed, modstandsdygtighed over for let ældning og god klorbestandighed.stærk væveevne. Bem...

Se detaljer

Karakter: MY12-serien Anvendelse: Optik, specialfibre kemisk fiber. Ydeevne: Hydrolysebestandighed, god overfladekvalitet, høj rundhed, højtryksbestandighed, høj brudforlængelse. Bemærk: T...

Se detaljer

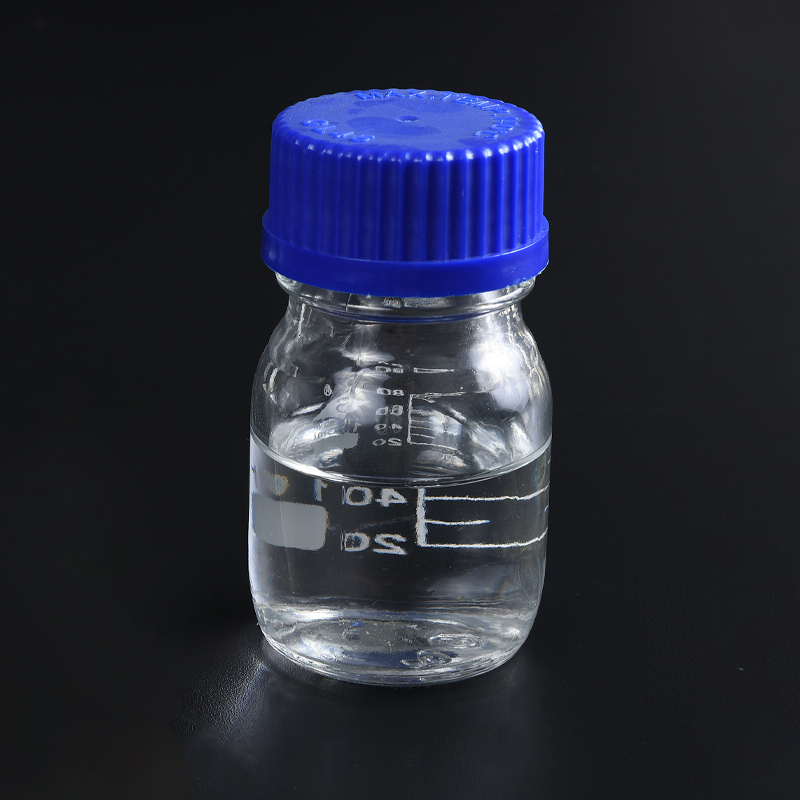

THF Molekylformel: C4H8O Farveløs gennemsigtig væske Er meget udbredt i organisk syntese, polymerindustri og som organiske opløsningsmidler.

Se detaljer